Reconstruction of a central [Fe]-Hydrogenase metallocofactor in a test tube

A new step towards the use of hydrogen biocatalysts

Following their elucidation of protein structures and biosynthetic sequences, scientists from Marburg, Lausanne and Minnesota developed a way to biosynthesize a crucial part of the enzyme [Fe]-hydrogenase that catalyzes the production of Hydrogen. Their findings represent a further step towards using Hydrogen as a green energy carrier in an environmentally friendly way.

Hydrogen gas (H2) is a promising energy carrier because its combustion produces only water as a waste product. However, for H2 production and utilization, as in fuel cells, platinum catalysts are used, a noble metal that is both rare and expensive.

Nature, in contrast, already carries the blueprints for sustainable hydrogen utilization: Since earth`s ancient times, microorganisms make use of hydrogenases, enzymes that consist of protein components and metallocofactors. A team from the Max-Planck Institute for terrestrial Microbiology in Marburg, the EPFL Lausanne and University of Minnesota were now able to recreate the central metallocofactor of the enzyme [Fe]-hydrogenase in a test tube.

[Fe]-hydrogenase is one of three types of hydrogenases and is found only in methanogenic archaea, which produce methane from CO2 and H2. The research group of Max Planck scientist Dr. Seigo Shima is studying the catalytic mechanism of this unique enzyme, aiming to develop new catalysts. The group has already proposed the structure of several precursors and enzymes involved in biosynthesis. However, a thorough understanding of the underlying basic mechanisms is crucial to reaching any success in this regard.

“As the enzymatic reaction is reversible, biological methods that copy the active centers of hydrogen-splitting enzymes would have great potential for both the production and utilization of Hydrogen. However, in order to use and optimize these enzymes for industrial application, we first need to understand the basic principle of their biochemical actions, “says Seigo Shima.

Production of FeGP cofactor

A central element of the enzyme is the FeGP cofactor that is part of the enzyme`s active site. The cofactor contains carbon monoxide and acyl-ligands bound to iron. Now the researchers have been able to identify the key component of this cofactor, the biosynthetic precursor of the acyl ligand that is essential for catalytic activity. First author Sebastian Schaupp explains: “We used chemically synthesized precursors to test them as building blocks of the cofactor. By using an archaeal cell extract, we were able to create the FeGP cofactor from chemically synthesized and endogenous precursors and enzymes.”

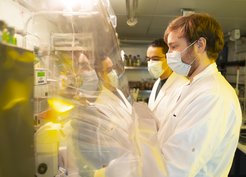

This combination of synthetic precursors and biological materials enabled for the first time to replicate the natural biosynthesis process outside of a living cell. The unique properties of this cofactor come, however, with a challenge: the cofactor is sensitive to oxygen and blue light and therefore most experiments have to be conducted under special protective conditions in an anaerobic chamber. Especially the oxygen sensitivity remains one of the major obstacles in the industrial application of hydrogenases.

In the future, the described method that was published recently in in the scientific journal "Angewandte Chemie International Edition" can be used to elucidate the unknown biosynthetic reactions. This could open up the possibility to synthesize variants not known in nature with unique capabilities for H2 for utilization under air.